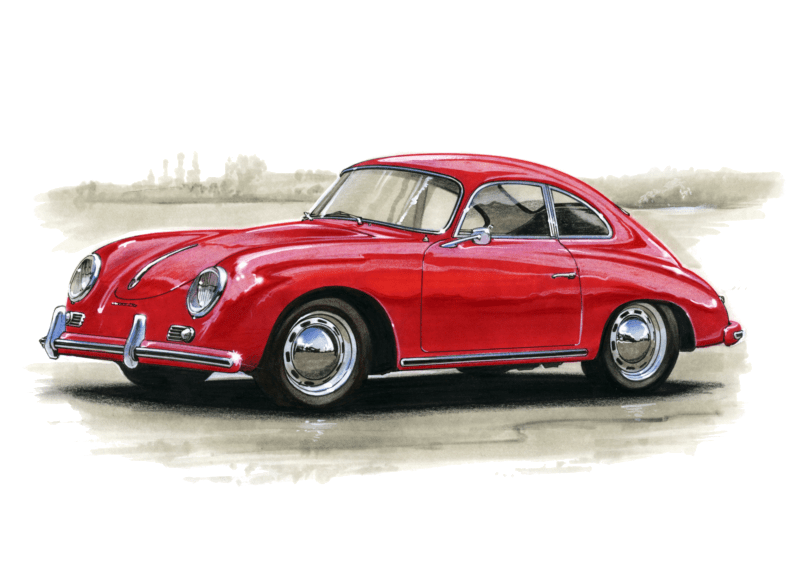

The Porsche 356 is an iconic sports car that is renowned for its sleek design and high performance. When it comes to building a car, the choice of materials is crucial in ensuring its durability, functionality, and overall performance. In the case of the Porsche 356, several materials were employed to construct its body, contributing to its exceptional quality and unmatched driving experience.

One of the primary materials used in the construction of the Porsche 356 body was steel. Steel is known for its durability and strength, making it an ideal choice for providing structural integrity to the car. Steel panels were employed in various parts of the body, such as the fenders, doors, and roof. These steel components offered the necessary rigidity to the vehicle, ensuring safety and stability even at high speeds.

However, despite its many benefits, steel also possesses some drawbacks. It can be heavy, which can impact the overall weight distribution and therefore the performance of the car. To address this issue, the Porsche 356 also incorporated lightweight materials into its construction.

One such lightweight material was aluminum. Aluminum was used in various aspects of the Porsche 356 body, including the hood, engine cover, and bumpers. Aluminum offers exceptional strength-to-weight ratio, meaning it provided the necessary strength while significantly reducing the overall weight of the car. This reduction in weight translated into improved fuel efficiency and enhanced handling, making the Porsche 356 a joy to drive.

Another material used in building the Porsche 356 body was fiberglass. Fiberglass was predominantly used for the body panels, including the front and rear wings. Fiberglass is renowned for its lightweight nature, corrosion resistance, and versatility. The use of fiberglass allowed for more intricate designs and improved aerodynamics, contributing to the car’s overall performance and aesthetics.

The body composition of the Porsche 356 was a blend of these materials, strategically selected to achieve the desired balance between strength, weight, and performance. The combination of steel, aluminum, and fiberglass resulted in a car that was not only robust and durable but also agile and nimble on the road.

Additionally, the use of these materials allowed for easier production methods, enabling the mass production of the Porsche 356 without compromising its quality. This helped make the Porsche 356 more accessible to a wider market, solidifying its position as a classic sports car loved by enthusiasts worldwide.

In conclusion, the body construction of the Porsche 356 incorporated a blend of materials, including steel, aluminum, and fiberglass. Each material served a specific purpose, with steel providing structural integrity, aluminum reducing weight, and fiberglass enhancing aerodynamics. This combination of materials played a vital role in creating a car that was not only visually appealing but also offered exceptional performance and unmatched driving experience.